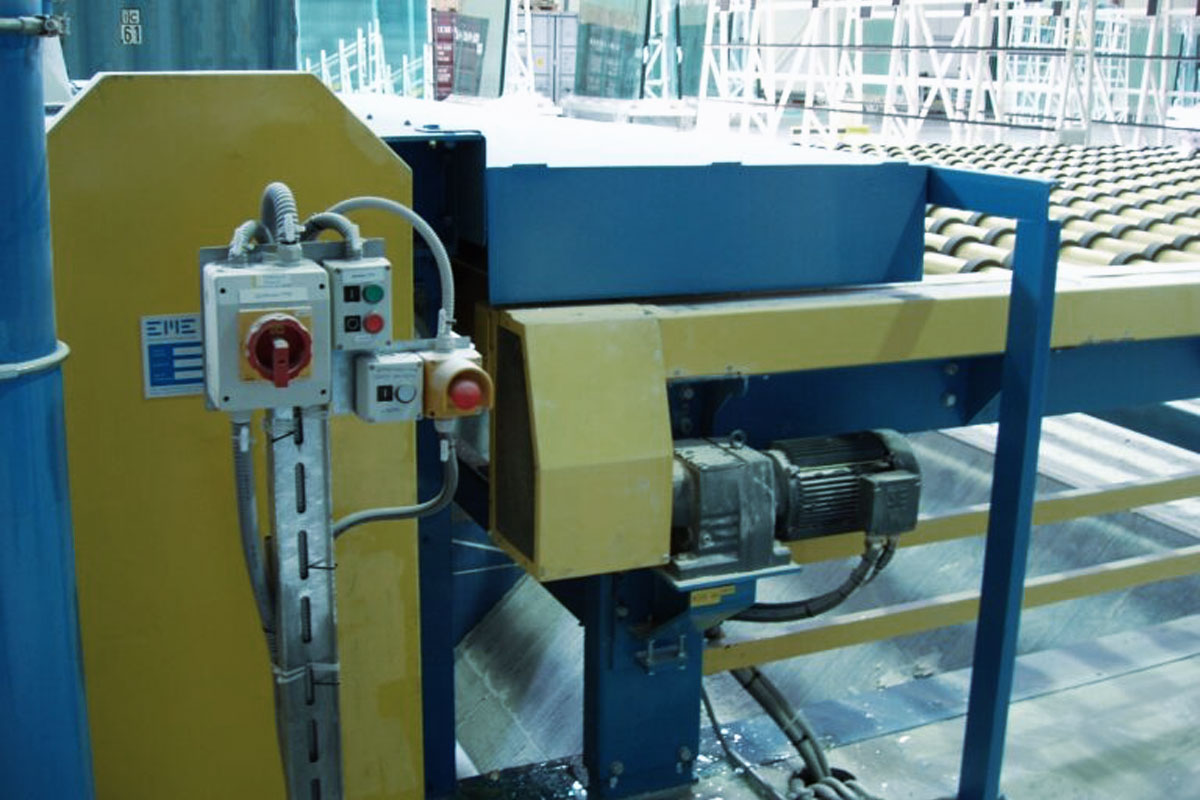

Plate crusher

This equipment is used under the roller conveyor to break whole glass plates, creating tiny pieces of glass and simplifying transportation.

Edge trim crusher

The job of an edge trim crusher is to cut off the edge stripes on both sides of the glass plates.

End of line crusher

This machine is ideal for pre-crushing glass plates at the end of the trimming line.

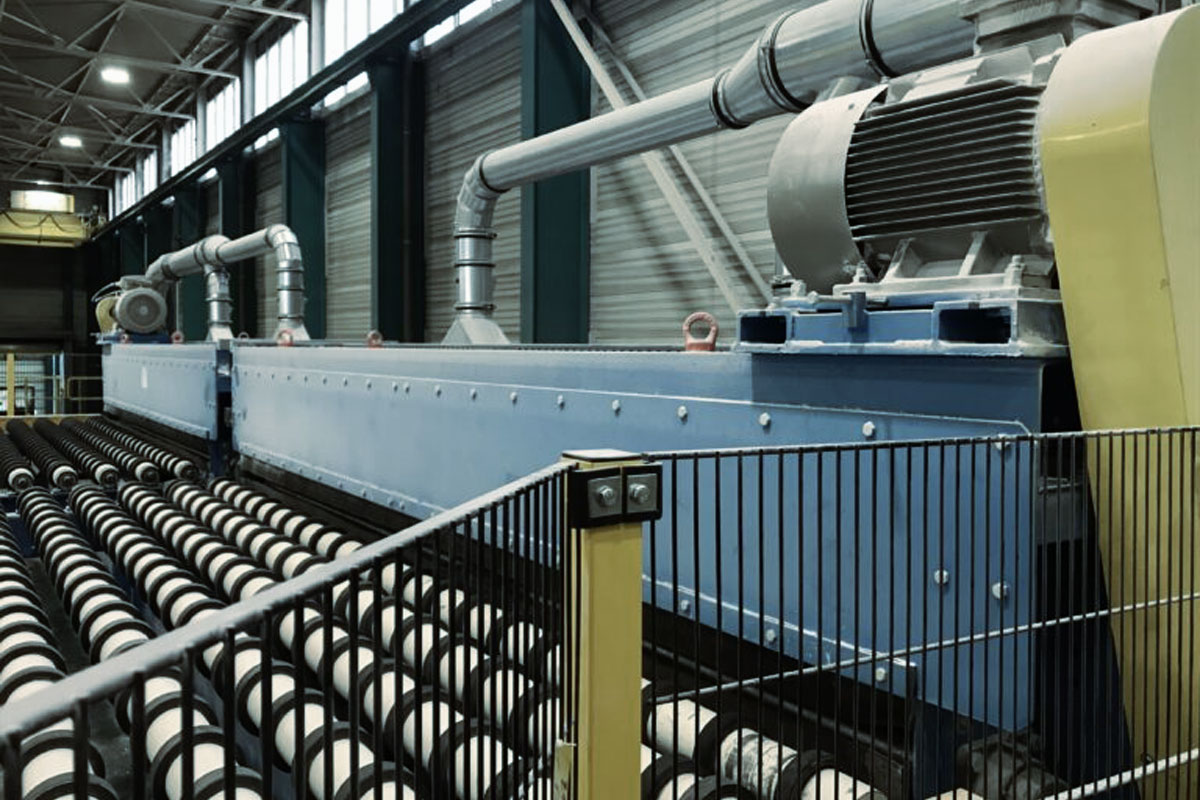

Float crusher

Various types of float crushers are required to automatically reject defective glass plates without interrupting the float glass process on the trimming line. Each EME float crusher will be specially designed accordingly to customers’ requirements regarding the width of the glass plate and thickness.

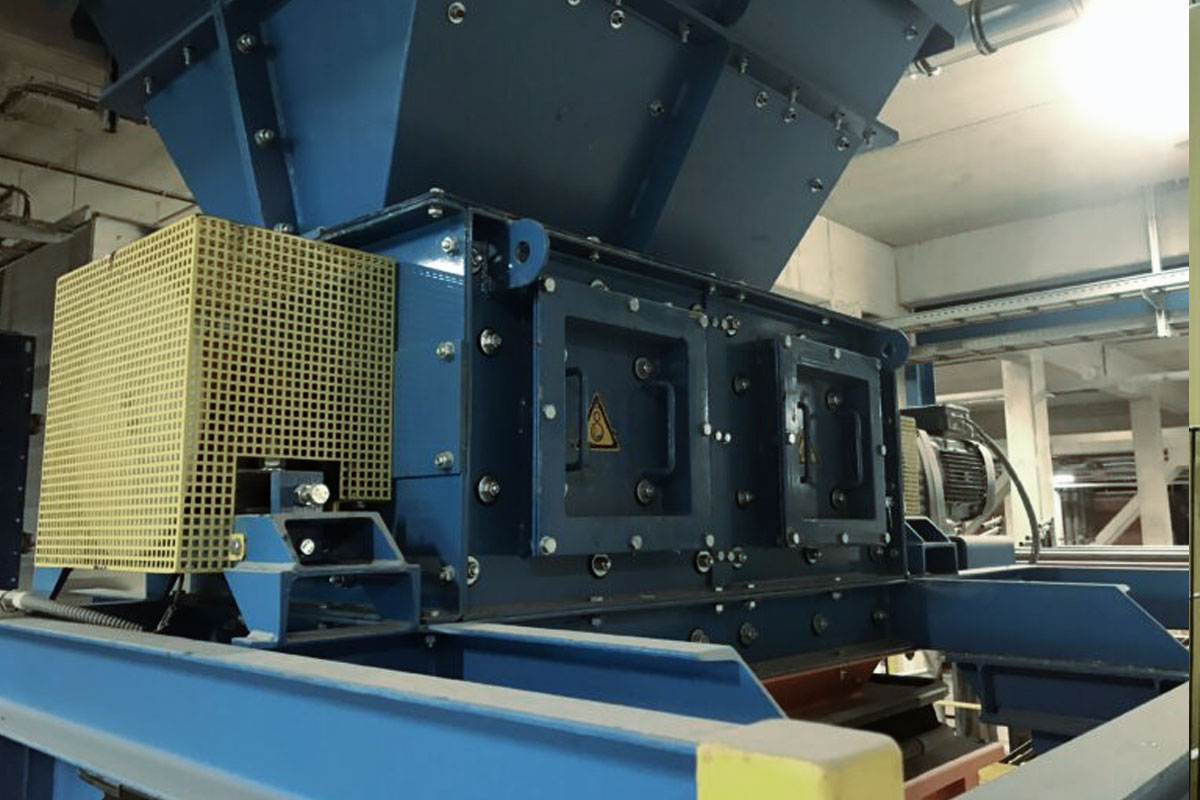

Float Hammer crusher

It’s a specially designed crusher for the final crushing of the float glass in the cullet return system.

Winch crusher

This equipment is ideal for glasses with 1 to 6 mm of thickness.