Tailor-made batch and cullet solutions for the container glass, flat glass, fibreglass, tableware and other particular glass industries.

Process and technology

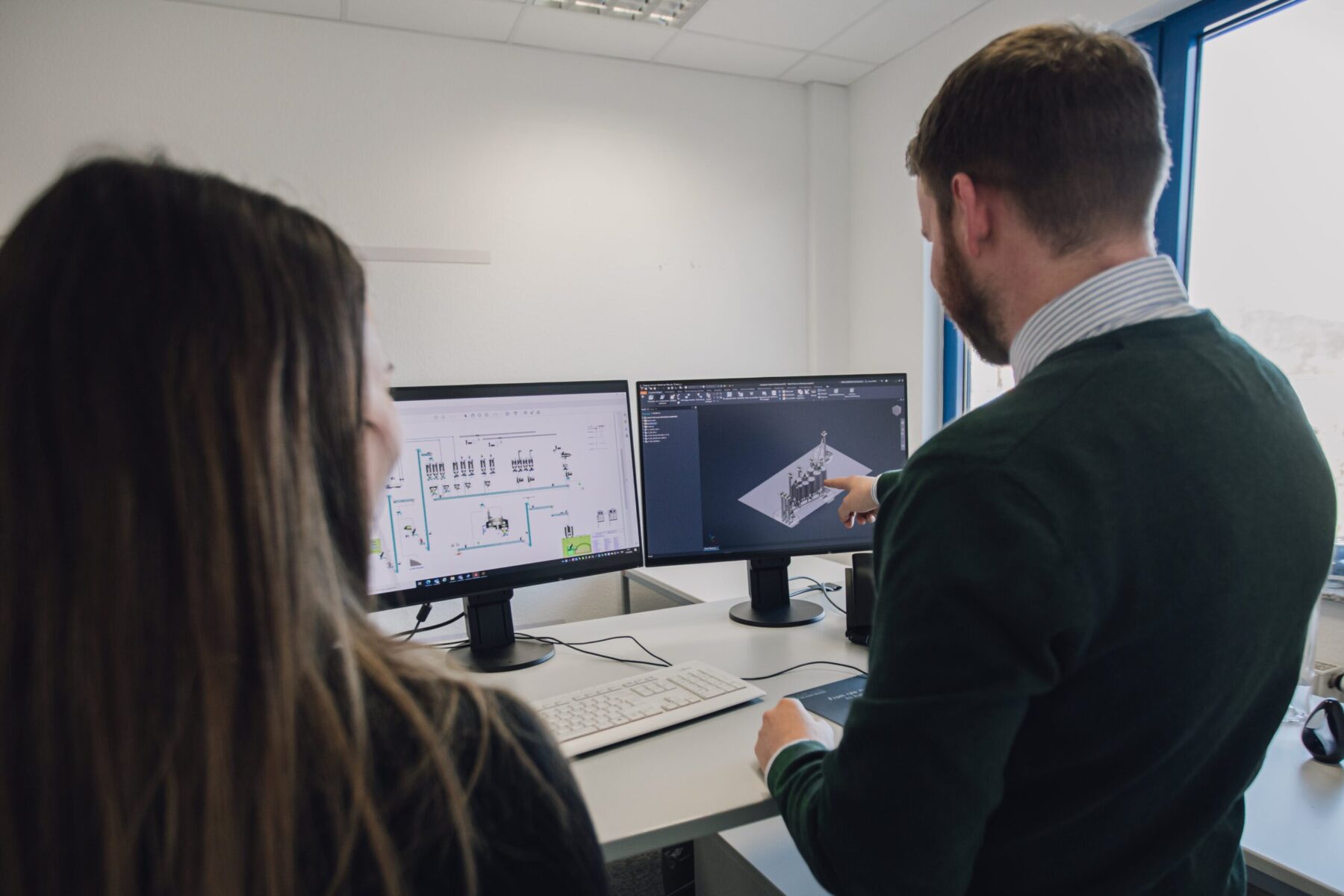

- Customised layouts and concepts, specialised process experience, computerised design calculations, detailed engineering, automated 3D modelling, plant automation and software programming.

- In-house engineering, construction and supervision.

- Reliable and robust design, high efficiency, low maintenance requirements, specialised support personnel and proven quality management system.

Whether it is due to a plant expansion, the need to substitute old equipment with modern ones, or to reduce cycle times, EME has the best solutions for a batch plant upgrade. Every consideration is given to achieve the best value for money, plant lifetime expectations and future expansions or modifications.

Engineering and construction

- Reliable and robust design, high efficiency and low maintenance requirements

Process and technology

- Customised concepts, deep knowledge and experience, computerised design calculations, plant automation and software programming

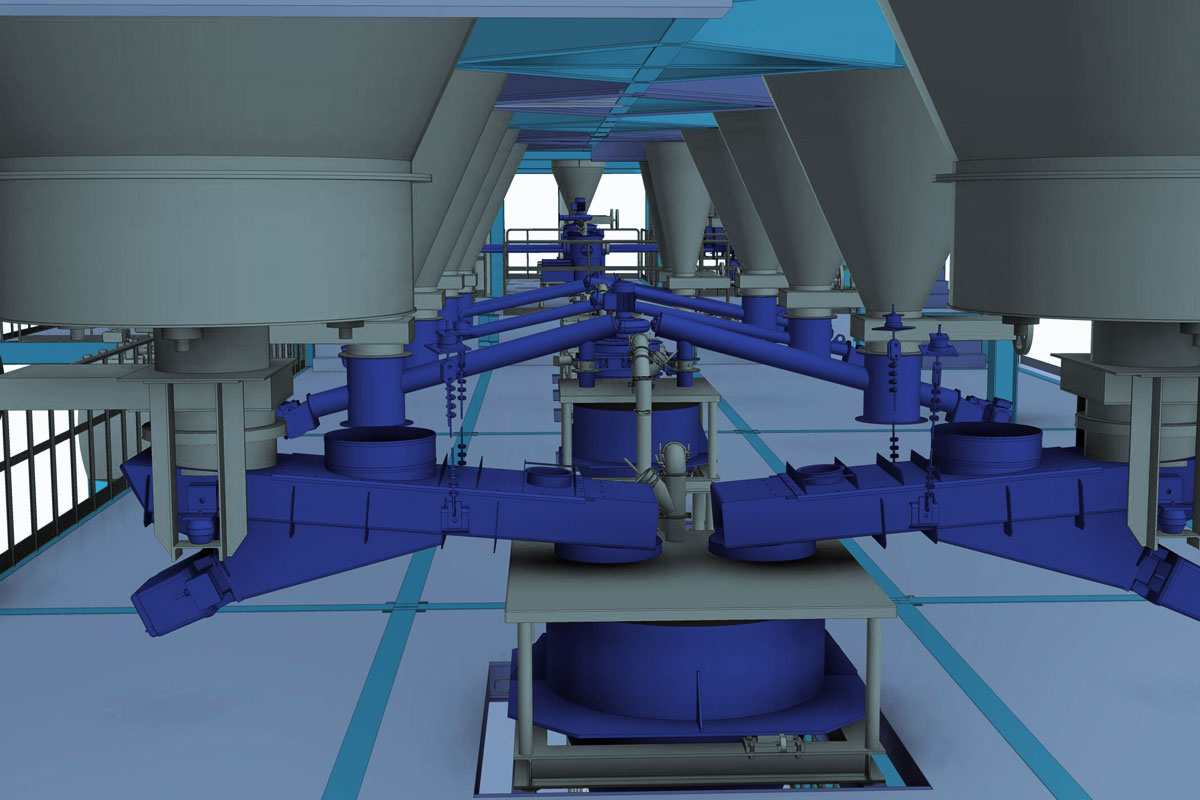

Functional groups

- The set-up of single functional groups determines the process flow and parameters.

- The number of weighing lines, mixers and furnaces affects the complexity of functional groups

Batch plants worldwide trust EME’s electric control and automation system to monitor their process, taking advantage of its simple, robust and reliable interface and structure. Complete with EME’s unbeatable customer service, our simple yet comprehensive electric control and automation system is fully customisable to fit all glassmakers needs.

Electric control

- Innovative hardware design

- Simple electric cabinet construction

- Software programming and process control system generation based on a programmable logic controller (PLC)

- Installation and commissioning (cold and hot)

- CE, UL and Gost certified

Installation

- EME can work on a turn-key basis and offer any job sharing (engineering and key equipment)

Cold commissioning

- During the cold start-up, all drive systems are checked

- Frequency converters and soft starters are also parameterised

Hot commissioning

- For the hot commissioning, EME software engineers activate the operating and control software and calibrate scales

The EME project manager is responsible for planning, organising and directing the completion of the project while ensuring it is delivered on time and within scope. Throughout, the EME project manager will outline key deliverables and milestones and identify the tasks that must be completed. The EME project manager will communicate internally (with the members of the team) as well as externally (with the sub-suppliers and customer).

When unforeseen problems affect your batch plant, EME provides real-time and immediate support. Wherever a plant is located, we can analyse, advise and optimise it remotely via a secured virtual private network (VPN).

The remote commissioning of a batch plant involves two stages: the cold start-up and the hot commissioning. During the cold start-up, all drive systems are checked. Frequency converters and soft starters are also parameterised.

For the hot commissioning, EME software engineers activate the operating and control software and calibrate scales.

EME offers a wide range of after-sales services, including planned and on-demand services.

On-demand

- The on-demand service requires immediate responses, including remote access to the control system and onsite interventions

Planned services

- The planned services are functional checks, audits, upgrades, health & safety checks and preventive maintenance

Under maintenance contracts, service technicians can inspect a batch plant on a regular basis (e.g., four times a year).

We want our customers to make the best possible batch for a high-quality glass product. But this is just part of our goal. We also work to reduce downtimes and failures, and create a clean, safe and healthy environment for the operators. That’s why we offer technical support and consulting for our clients.