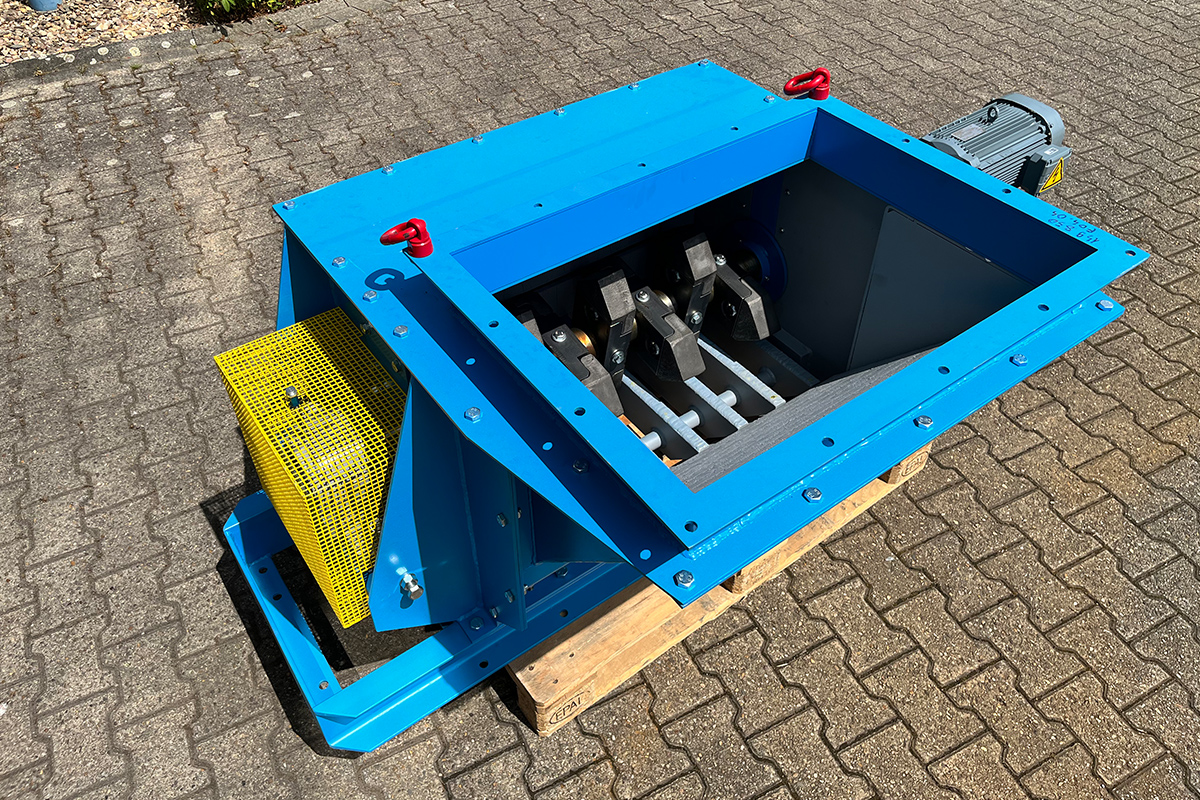

Hammer crushers

This equipment is used at the cold end of a container glass production line. Containers rejected during an inspection are passed through a feed opening into the striking arc of the rotating hammers.

Several models are available, with capacities ranging from 5 to 25 t/h.

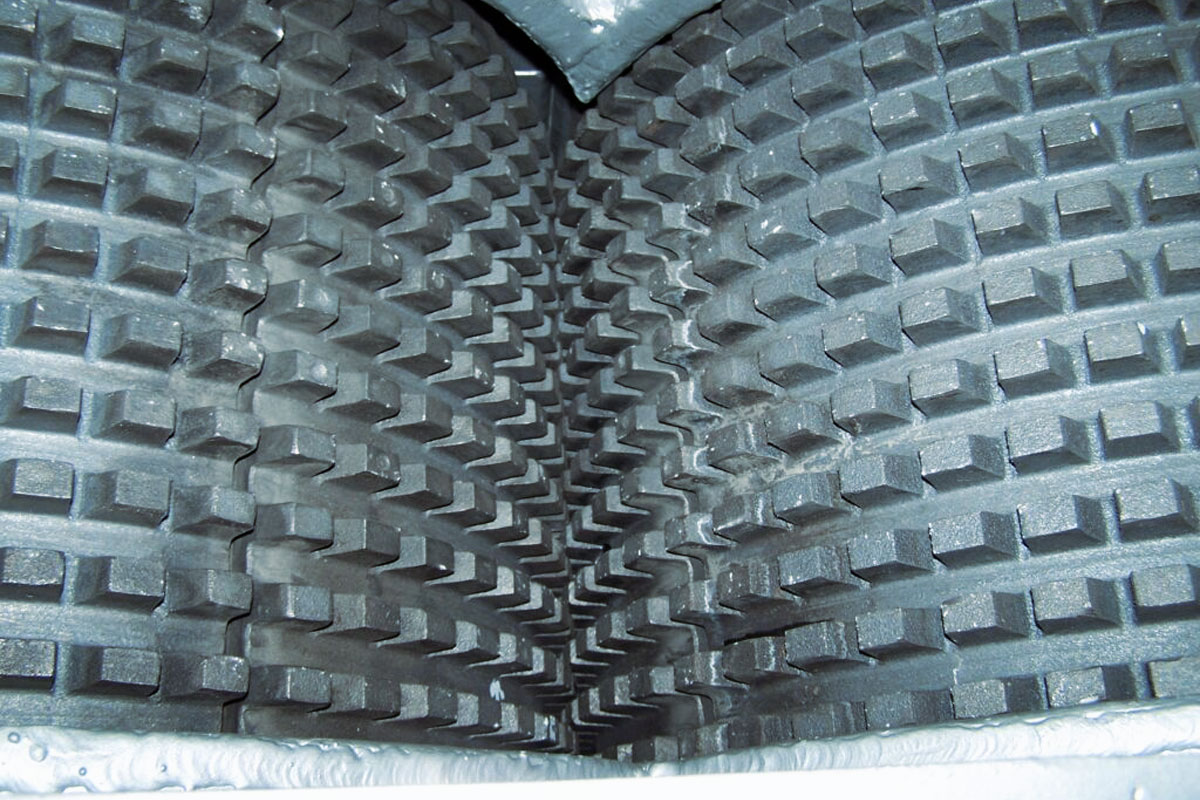

Double-roll crusher

Double-roll crushers can be used for small glass containers or as a second stage after a hammer crusher. Double-roll crushers can produce a defined particle size distribution, create less dust than hammer crushers and are quieter when operating.

A vast range of double roll crusher models is available, with capacities varying from 7 to 24 t/h.

Secondary crushers

Another type of crusher is the secondary crusher. It’s mainly used as a pre-crusher for glass containers.